Finetech is the leading equipment manufacturer for sub-micron die bonding and advanced SMD rework.

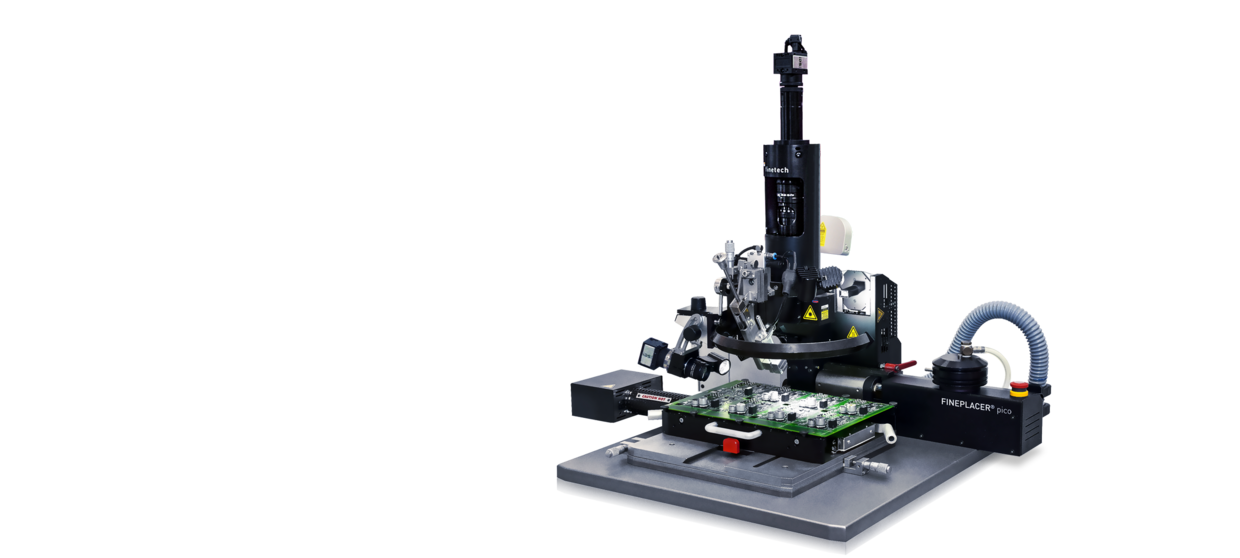

FINEPLACER® pico rs

Hot Air SMD Rework Station

The system is a bestseller for professional mobile device rework in high density environments. A high level of process modularity allows all rework process steps within one system. The FINEPLACER® pico rs system is at home in R&D, process development, prototyping and production environments.

Application area from 01005 up to large BGA on small to medium sized PCBs, with the goal to have highly reproducible soldering results.

EXPERT 04.6 IXH

Manual rework of BGA, QFP and sockets.

The EXPERT 04.6 IXH Rework station provides the ideal support for manual rework tasks. Its compact design provides all functions necessary for the reworking process, from desoldering, placing and soldering in components as well as removing old solder. Aligning and placing components can be done reliably, and MARTIN’s tried-and-tested heating technology guarantees the optimal soldering results. The Rework stations are controlled by EASYSOLDER 07 software, through which a clear and structured overview is provided of all profiles and configurations within the repair process.An infrared under-heating system is integrated into the workstation to provide the ideal conditions for the respective areas of application. And the precise and efficient hot-air top heater complements the overall heating concept. Furthermore, the Auto-Profiler included within the software automatically aligns the top- and under-heating system to your desired process parameters.

MINIOVEN 05

Compact hybrid reflow oven

The MINIOVEN 05 is a compact and robust table-top device specially designed for reballing of BGAs and prebumping of QFN components. The device is used in development and production. The efficient hybrid heating technology heats up electronic components evenly from all sides and thereby guarantees reproducible reballing results. Up to 25 heating profiles can be set up, administered and saved through the intuitive menu navigation.An additional external temperature sensor is used to ensure the highest possible reliability as the device automatically adjusts the reballing profiles. Through the sensor, the optimal profile settings for achieving the specified component temperatures are determined through the sensor. The EASYBEAM software allows for the convenient editing of reballing profiles as well as for the temperature history to be depicted. Aside from the reballing process for BGA components, there are also images and provisions available for the prebumping of QFN components. The device possesses a connection for process gas. This allows the reflow processes to be easily converted to nitrogen-based atmospheres.