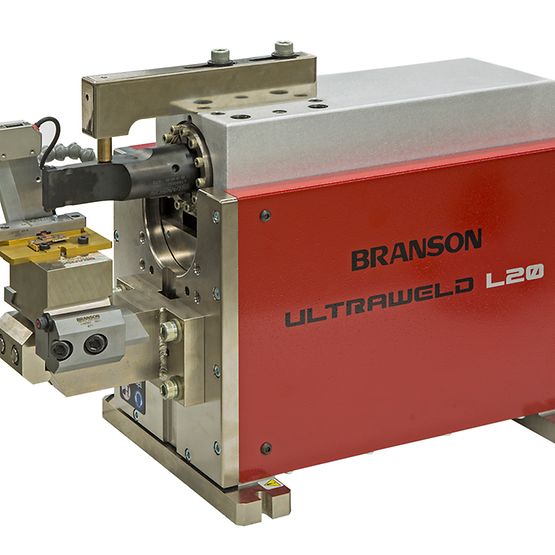

Ultraweld® L20 System

- A precision roller bearing slide to assure smooth operation and extreme accuracy.

- Precise adjustments for accurate setting of both upper and lower positive stops.

- Conveniently located flow controls offering easy adjustment of head speed in both directions.

- A polar mounted ultrasonic stack to facilitate linear and axial setup and efficient transmission of ultrasonic energy to the horn.

- Titanium horns with low cost replaceable tips or solid tool steel horns for fast setup and minimum tooling cost.

- Fixturing which is changed quickly and easily for various applications by means of a dovetail mounting.

- Optional vortex cooling to allow high-speed operation without heat buildup.

- Ultraweld® L20 – 20 kHz Welding System rugged and easily tooled for a wide range of nonferrous welding applications.

Ultrasonic Splicing System

- Special ‘keyed connector’ (single point) air and electrical disconnect permit instant replacement of a production actuator at the workstation in under two minutes for off-line maintenance and maximum production.

- Critical tooling clearances and alignment do not change with use.

- Precise, programmable adjustment of splice width

- Electronic pressure regulator to accurately control splice force

- Electronic amplitude control for precise one-micron adjustment

- Quality limits stored in system memory for instant recall and automatic setup